Packaging Audit Report (P.A.R.)

P.A.R. (Packaging Audit Report) is a comprehensive, data-driven assessment designed to optimize your folding carton packaging.

It goes beyond inspection — delivering actionable insights that enhance quality, cost efficiency, and sustainability across your packaging supply chain.

Why a Packaging Audit Matters

At Beneco Packaging, precision starts in our in-house Quality Lab Room — the analytical core of our exclusive Packaging Audit Report (P.A.R.) program.

Every P.A.R. is built on real data gathered from this lab, where our engineers measure, verify, and document packaging performance across multiple technical parameters. Our experts assess every stage of your packaging—from structural strength to print consistency—to uncover opportunities for optimization. Each report includes a detailed scorecard and actionable improvement roadmap to help you achieve best-in-class packaging performance.

Our Core Audit Framework

Score / Crease Bending Test

Measures the resistance and flexibility of folding lines to prevent cracking or uneven bends.

Guarantees clean, consistent folds for high-speed auto-packing lines.

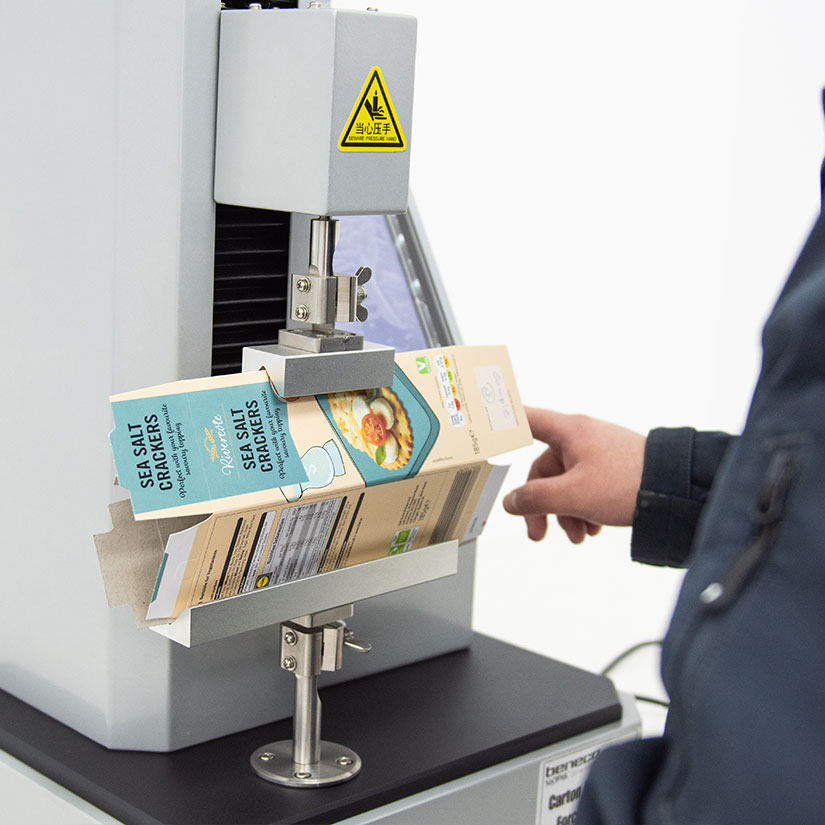

Carton Opening Force Tester

Evaluates the force required to open cartons to ensure optimal usability and performance.

Prevents open seams, tearing, and downtime on automated filling lines.

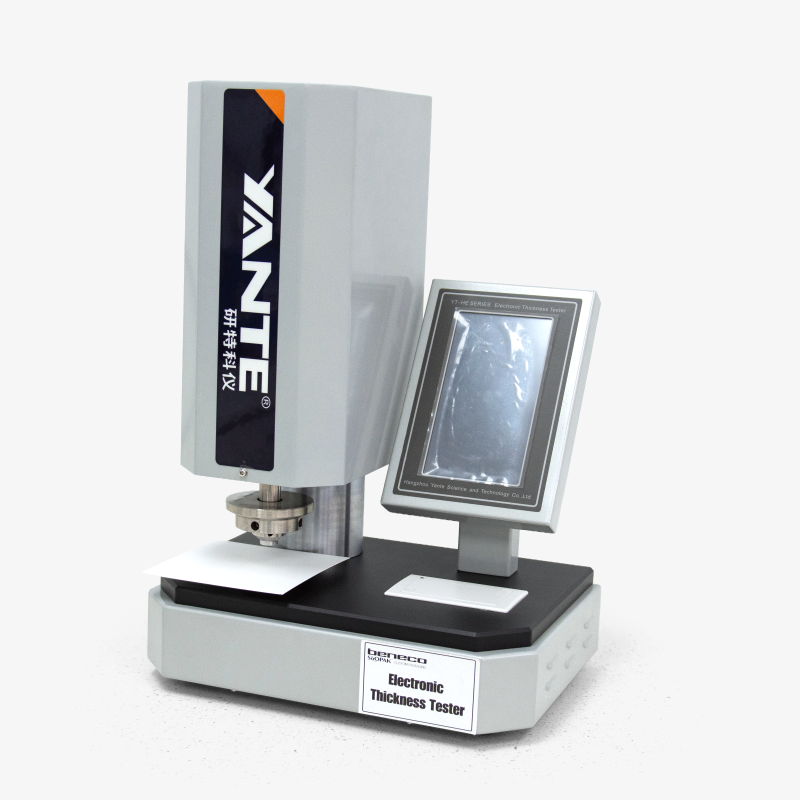

Caliper Measurement

Aka Board Thickness,Checks paperboard thickness and uniformity to verify material specifications.

Ensures stiffness, folding accuracy, and reliable protection for every product.

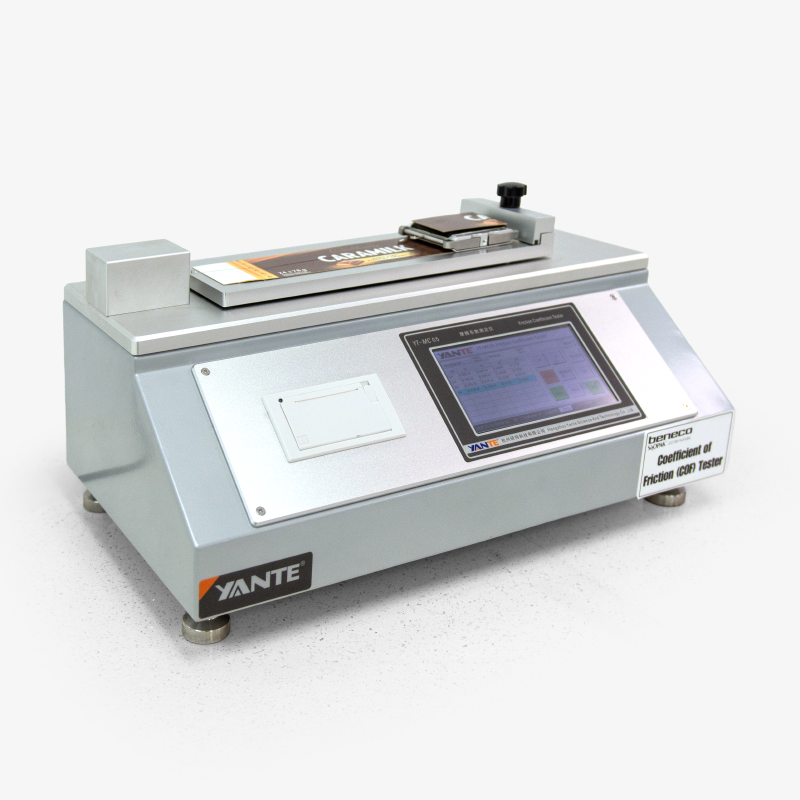

Coefficient of Friction (Slip Test)

Analyzes surface friction between cartons to assess feeding behavior on production lines.

Prevents slippage, double-feeds, and line jams while optimizing coating performance.

Rub Test

Aka Ink Abrasion Resistance, Tests print durability and abrasion resistance during handling and shipping.

Prevents scuffing, fading, or surface damage, maintaining a premium shelf look.

Compression Strength Test

Aka Box Load Performance, Measures how much vertical load a carton can handle before collapsing.

Ensures cartons withstand stacking, transport, and palletizing without damage.

Ink Density & Colour Consistency

Ensures accurate and consistent color reproduction across all printing batches.

Maintains brand integrity, prevents shade shifts, and meets GMI/PQA print standards.

Moisture Content Analysis

Monitors paperboard moisture levels to prevent warping or brittleness.

Maintains dimensional stability, ideal folding, and strong adhesive performance.

Together, Beneco Lab ensure every carton is evaluated not just by appearance — but by measurable performance.